limitations of brinell hardness test and why|brinell hardness number chart : importer Brinell hardness testing has its limitations, however, including the need to use a selection of different-sized indenters depending upon the material under test and, sometimes, it’s not suitable for testing very small components. 16 de agosto de 2021 13 músicas, 36 minutos ℗ 2021 Mussoumano. Disponível também na iTunes Store. Ouça Mussoumano Beats de MUSSA no Apple Music. 2021. 13 músicas. Duração: 36 minutos.

{plog:ftitle_list}

webDemi Sutra photos, including production stills, premiere photos and other event photos, publicity photos, behind-the-scenes, and more.

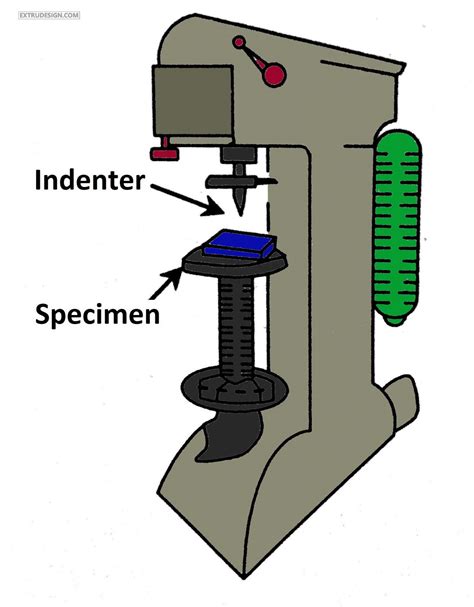

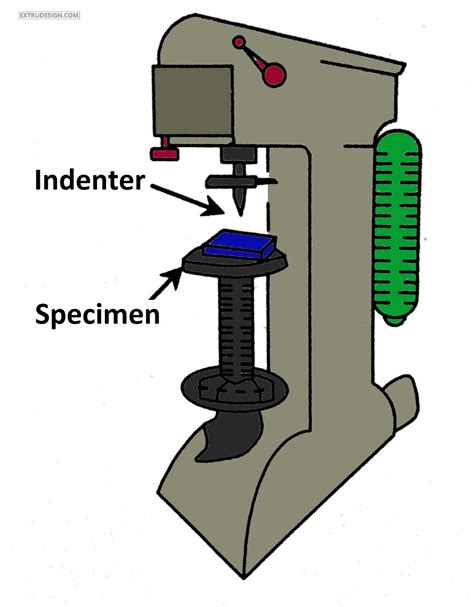

What is Brinell Hardness Test? The Brinell Hardness Test is a way to measure how hard a material is by pressing a hard ball into it and seeing how big the dent is. What are the advantages and disadvantages of Brinell Hardness Test l Longer testing time: Generally speaking, the Brinell test requires more time than Vickers or Rockwell methods for determining hardness. l Requires more maintenance: Regular .Understanding the limitations of the Brinell Hardness Test is essential for mitigating potential errors and ensuring the reliability of hardness measurements.In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is the most commonly used hardness measurement .

Brinell hardness testing has its limitations, however, including the need to use a selection of different-sized indenters depending upon the material under test and, sometimes, it’s not suitable for testing very small components.

The Brinell test has several limitations; 1. Cannot be used on soft materials. 2. The test may not be valid for thin specimens. The minimum thickness is about 0.313 in. 3. The test is not valid .Therefore good illumination of the test indent is important for ensuring correct evaluation of the test indent (e.g. with the aid of a ring light). Limitation in applying the method on thin .

Request Quote. The Brinell hardness test is a commonly used hardness testing method that measures the hardness of materials. It does so by pressing a hard ball indenter into the surface of the material under a specified .The Brinell Hardness Tester, a widely used method for assessing material hardness, offers several advantages and limitations that are important to consider when performing hardness testing. Understanding both the .

brinell hardness testing procedure

The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell .Advantages of Brinell Hardness Test. Simple setup and operation – The Brinell Hardness Test is easy to set up and use, making it accessible for various users without the need for extensive training.; Wide material applicability – It works .Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy.The large size of indentation and possible damage to test-piece limits its usefulness. However, it also had the useful feature that the hardness value divided by two gave the approximate UTS in ksi for steels.

The Brinell Hardness Tester, a widely used method for assessing material hardness, offers several advantages and limitations that are important to consider when performing hardness testing. Understanding both the strengths and weaknesses of the Brinell Hardness Test is crucial for obtaining accurate and reliable hardness measurements.

The Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His solution was to press a railway wheel-bearing ball into the material and then measure the size of the mark it left. The method proved reliable and in 1900 the .

Each method has its advantages and limitations, and the choice of method depends on the material being tested and the . Brinell hardness testing is extensively used in the casting industry to assess the hardness and quality of cast materials, such as cast iron, aluminum alloys, and bronze. It provides a reliable measurement of the material . Hardness testing is a crucial aspect of metallurgy, as it provides valuable insights into a material’s mechanical properties and overall quality. There are various methods available for measuring hardness, each with its own set of advantages and limitations. In this blog, we’ll delve into the Vickers Hardness Test and discuss when it’s best to use this method over other .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .The Brinell hardness test is a method used to measure the hardness of materials, particularly metals, by indenting the surface with a hard spherical ball under a specified load. This test provides valuable information about the material's ability to withstand deformation and wear, which is closely related to surface hardness and elasticity. The diameter of the indentation left .

Question: Why should a different testing device be used if the Brinell hardness is above 630? 2. Explain the limitations of Brinell and Rockwell testers? 3. Why was it necessary to grind the sample being used in the Rockwell tester but not in the Brinell tester? 4.Brinell hardness test uses a steel or tungsten indenter of a specified size and a specified load to make an indent on the test sample. IV. Advantages and Disadvantages of Brinell Hardness. Advantages: The Brinell method does not require the test sample to be prepared for inspection. This method can be used to test materials with irregular surfaces.Duration of Brinell and Rockwell Hardness; The Brinell test is very slow (30 – 60sec). . Disadvantages of Brinell and Rockwell Hardness; Disadvantages of Brinell’s method are that hardness of ≥ 650 HB cannot be measured; the hardness is dependent on the load and according to X (degree of load) so it is necessary to choose the . The Brinell Hardness Test is a straightforward process that is often applied to materials with rough structures, like cast irons or forged metal samples. During the test, a 5mm or 10mm round carbide ball is pressed into the material using a very high test load, usually between 750kg and 3000kg. This action creates an indentation that is .

The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested .Hardness tests of metals are essential to manufacture reliable big machines and automobiles. The hardness test should be first selected according to the needs of the material. You can find answers to questions about the Brinell and Rockwell in the article, as we have clarified the difference between the two tests. When the Brinell hardness test cannot be used, such as when the material’s HB value is greater than 450 or the sample size is too small, the Rockwell hardness test is used instead. This test involves pressing either a .An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm.This is applied under a load P of 500–3000 kg applied for 10–30 s.The diameter of the circular indentation d is measured in millimetres. The hardness number, (HB) is calculated using the following equation:

Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter .

The Macro Brinell hardness test Macro Brinell hardness test measurement is calculated by the formula in which the applied test force (kilograms) is divided by the surface area of the developed indentation (square millimeters). The final value is called a pressure measurement, but it has no unit. The Macro Vickers hardness test

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.The Brinell hardness test. The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically. Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Selection Table of Brinell Hardness Test P/D 2. Material type: Brinell hardness number/HB: . Traditional hardness measurement is only applicable to large-sized samples, not only due to limitations of the .

The speed of the method is not very efficient relative to Brinell or Rockwell hardness test. Apart from the time which is consumed for the preparation of the test, it takes almost a minute to complete its cycle. . Every hardness test has its own advantages and limitations. In this article, the Vicker hardness test with its significance . This alternative to the Brinell test for measuring the hardness of materials facilitates the measurement because the necessary calculations are independent of the indenter size and it can be used for all materials regardless of hardness. The basic principle of Vickers hardness tester, as with all common hardness measures, is to observe the .

The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. .The validity period for the calibration of a given hardness reference block is specified in part 3 of the ISO standard published for the respective hardness testing process. The validity for steel hardness reference blocks should be limited to five years, whereas the validity period can be reduced to two to three years for aluminium and copper .

ultrasonic hardness tester krautkramer

ultrasonic hardness tester met-u1a

5 de fev. de 2015 · Internacional português cumpre exames médicos complementares esta sexta-feira

limitations of brinell hardness test and why|brinell hardness number chart